Hot New Products Ceramic Check Valve - knife gate valve with pneumatic actuator – GMK Valve

Short Description:

Hot New Products Ceramic Check Valve - knife gate valve with pneumatic actuator – GMK Valve Detail:

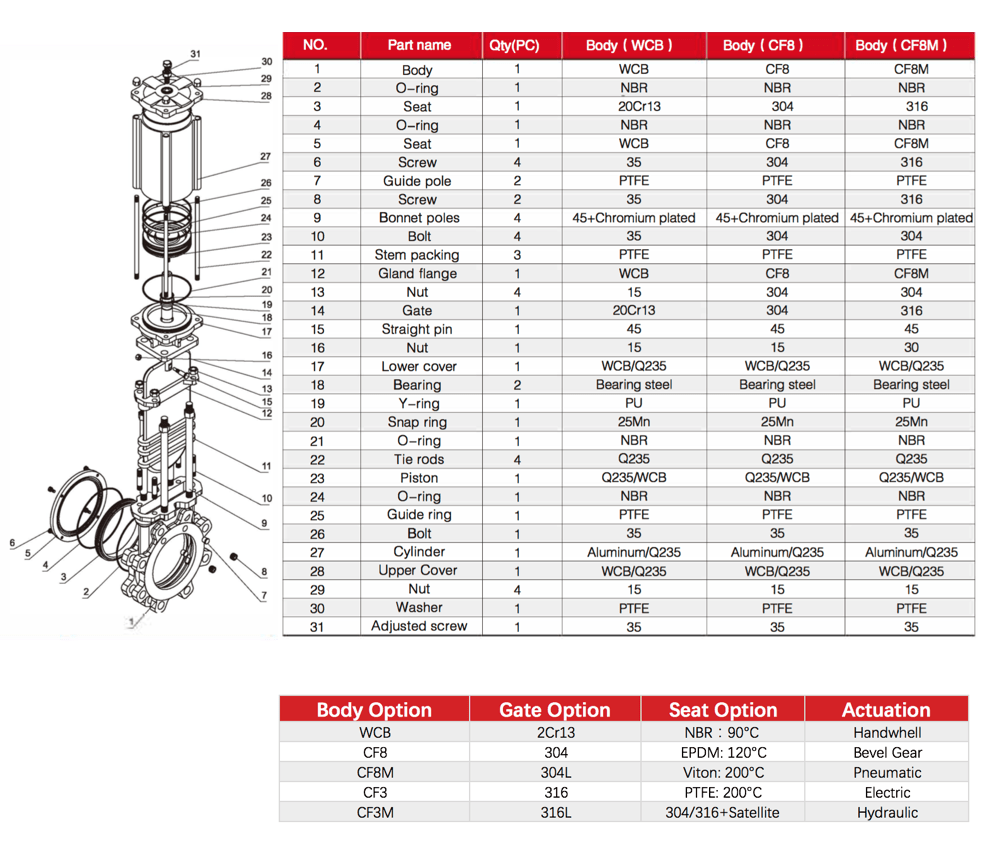

The knife gate valve is a unidirectional wafer knife edge gate valve used on industrial pipeline for on-off operation. The structure of body and seat eliminates clogging shutoff for flow with fine particles. Additionally, beveled knife edge helps the gate cut through thick media easily

According to different working situation: non-rising stem knife gate valve, wafer knife gate valve, lugged knife gate valve, pneumatic knife gate valve, electric knife gate valve, manual knife gate valve and bevel gear knife gate valve are all available.

Body:

- Guide claws design at the port bottom for gate fixture, instead of a groove, eliminates any potential clogging when valve shutoff.

- Integral body design ensures smooth flow, easy assembly and smaller shell leakage possibility.

Gate:

- Beveled knife edge provides strong cutting stress and tight sealing.

- PTFE resilient point guider above the port prevents metal-metal contact between gate and body.

- Gate thickness can be increased to meet higher pressure.

Seat:

- Side-entry seat is replaceable, reducing the cost of maintenance.

- Preloaded seat is adjustable to meet different sealing class and compensate normal seat wear.

- Seat retainer covers the side of seat and prevents seat from direct flow flushing.

Other

- Double thrust bearing minimize the torque required for operation.

- Stem Cover is available

- Grease Nipple is available

- Bearing Cover is available

Sizes Range:

DN 50~600mm NPS 2”-24”

(Large diameter on request)

Sealing Options:

NBR:90°C EPDM: 120°C

Viton: 200°C PTFE: 200°C

Metal seal :304/316+Satellite

Max Working pressure:

DN50~DN250: 10Bar NPS2~NPS10:150Psi

DN300~DN450: 7Bar NPS12~NPS18:90Psi

DN500~DN600: 4Bar NPS20~NPS24: 60Psi

Face to Face: MSS SP-81

Flange connection:

GB/T 9113.1, JB/T 79.1,HG 20592,

ASME B 16.5, EN1092-1 (other connections on request)

Operation Option:

Handwheel/Bevel Gear

Pneumatic

Application:

Pulp & Paper / Water & Waster Water /Mining / Metallurgy/

Petrochemical /Printing & Dying / Pharmacy/ Beverage & Food

Product detail pictures:

Related Product Guide:

Dr. Solomon L. Moshé Elected President of The International League Against Epilepsy | Pneumatic Actuator Valve With Limit Switch

Kawasaki Responds To 2019 Ducati Panigale V4 | Pneumatic Diaphragm Control Valve Modulating Valve

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Hot New Products Ceramic Check Valve - knife gate valve with pneumatic actuator – GMK Valve, The product will supply to all over the world, such as: Vietnam , Malaysia , Ecuador , We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!