Factory Outlets Dry Powder Fire Extinguisher Valve - Tilting Disc Check Valve – GMK Valve

Short Description:

Factory Outlets Dry Powder Fire Extinguisher Valve - Tilting Disc Check Valve – GMK Valve Detail:

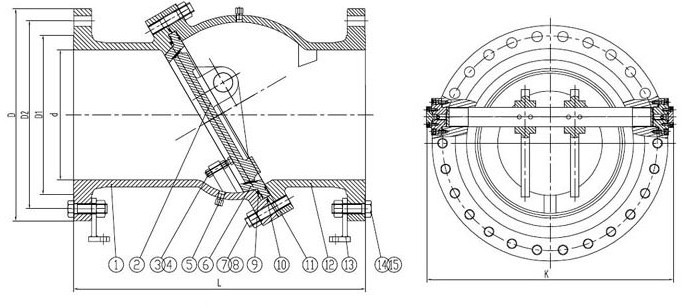

Product name:Tilting Disc Check Valve

Size:2″-36″

Rating:150LB,300LB,600LB,900LB,1500LB

Material:WCB, LCB,LCC, WC6,WC9, C5,C12,C12A,CF8,CF8M,CF3,CF3M,CN7M,B148,

ect

Connection:Flanges,RTJ Flange,Butt Weld

Feature:

1.Tilting disc check valves produce slightly more pressure drop than swing check valves of the same size. These check valves have a single-piece disc without a hinge. In response to flow forces, the disc pivots about hinge pins that are located within the geometry of the disc and slightly above the center-line of the valve body. Due to the disc rotating onto the seat, the sealing surfaces must be conical. Some tilting disc check valves include a counterweight on the disc, dramatically increasing the disc stability with lower flow rates.

2.Tilting disc check valves were designed specifically to minimize the potential for high-energy water hammer. This objective is accomplished by locating the disc center of rotation a short distance from its pivot point, thus allowing the disc to quickly close with flow stoppage or flow reversal. Although it is best to size this valve to be fully open, the disc is reasonably stable under some less than full-open flow conditions.

3.When it comes to maintenance, tilting disc check valves are more challenging than swing check valves. To keep seat leakage to a minimum, the conical seating surfaces of the disc and in-body seat must mate well, and the disc pivot location must be precise.

Standard:

1.Design and Manufacture:API6D,ANSIB16.34

2.Pressure-temperature rating: ASME B16.34

3.Face to face(end to end): API6D,API594

4.End Connection: 2″-24″ ASME B16.5; 26″ -42″ ASME B16.47; B.W end ASME B16.25

5.Test and inspection:API598,API6D

Product detail pictures:

Related Product Guide:

BMW F800GS vs. Triumph Tiger 800 XC | MC Comparo | Pneumatic Actuator Valve With Limit Switch

Plastic and Metal Butterfly Valves for pure and polluted materials by GEMU | Forged Valve

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for Factory Outlets Dry Powder Fire Extinguisher Valve - Tilting Disc Check Valve – GMK Valve, The product will supply to all over the world, such as: Durban , Mauritania , Norway , We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.